What is data standardization?

Data standardization in data management is converting raw data into a standard format and model that a computer can read based on the organization’s predefined rules. This helps maintain data accuracy and consistency and detect bad data throughout the entire data lifecycle management process.

Why do you need to standardize your data?

Every organization or system has its own limitations and conditions for its data management to stand ahead of its competitors and make them unique in the data-driven world. To achieve this, organizations transform their collected data into their standard format before they proceed with the business proposal effectively. Not only for the uniqueness, standardization works to address the data quality issues like duplicate, inconsistent, and irrelevant data roams in the dataset.

Significance of data standardization

Interoperability

Data standardization boosts internal systems and departmental connections. In oil and gas, data generated from exploration, drilling, and supply needs multiple systems to support; data standardization ensures uninterrupted data transformation and builds a stronger bridge for effective data communication.

Seamless data integration is highly possible by data standardization, especially in sectors like clinical trials and research in pharma and production lines, ERP, and supply chain in manufacturing, which assists organizations in making better decisions.

Improved data quality

The same formats, standards, and structures are created to form a single unified truth for the data generated from multiple resources; this ensures high-quality and accurate data by correcting data inaccuracy, removing dark data, and adding data value points to the dataset.

Data standardization strengthens regulatory compliance like GDPR, HIPPA, FDA, and EMA across industries like oil and gas, pharma, and manufacturing as it develops a harmonized structure.

Regulatory compliance

Standardized data helps industries meet industry-specific regulations and legal standards with the help of regulatory compliance, which reduces the risk of non-compliance and any other legal penalties. Regulatory compliance also strengthens data governance policies, security, access, control, credentials, and data assurance.

Improved collaboration and integration

In pharmaceuticals, collaborating data between drug discovery and development teams, research teams, and clinical trials is crucial. Standardized data provide a spotless combination of information from different teams and strengthen them with regulatory compliance.

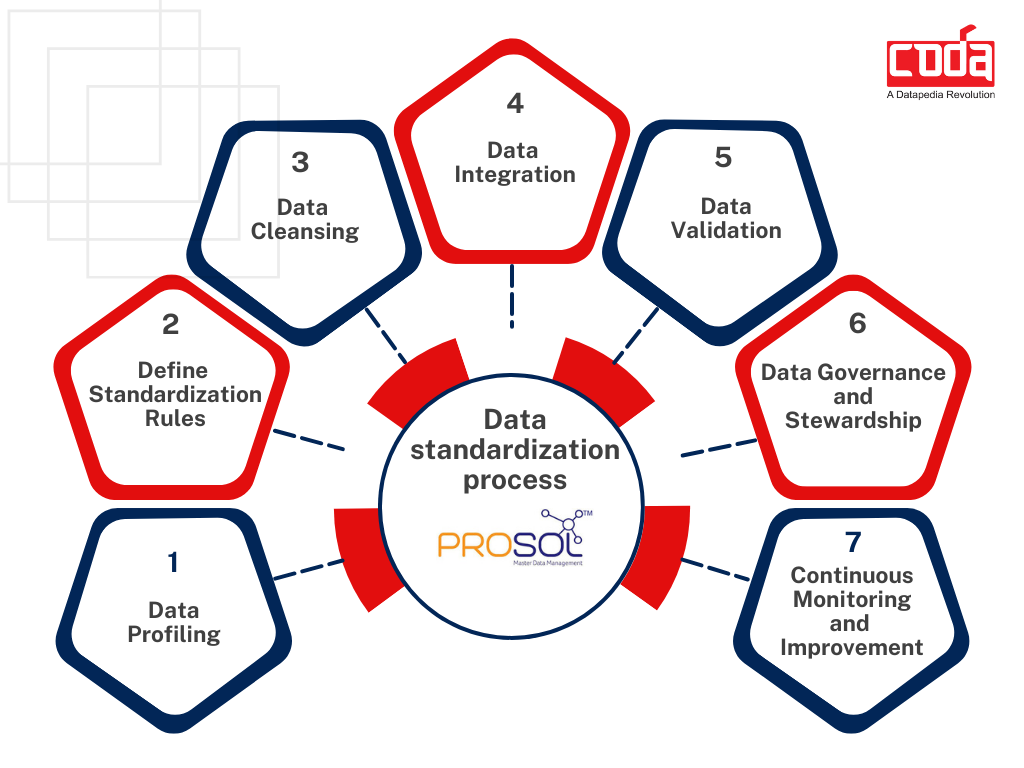

Data standardization process

- Data Profiling

- Define Standardization Rules

- Data Cleansing

- Data Integration

- Data Validation

- Data Governance and Stewardship

- Continuous Monitoring and Improvement

Data Profiling

Data profiling is the initial concept of reviewing and analyzing the current data set to understand its structure, formats, and standards. It examines inconsistent and missing values, removes duplicates, and performs data validation to ensure the data is ready for further usage. The purpose is to gain deeper insights into the database and make it accessible across various systems.

Define Standardization Rules

Implementing specific categories like names, phone numbers, dates, data codes, and specifications to form a standard format around different data sources. Developing a data dictionary that defines the terms and conditions for the stakeholders to establish uniform data formats and structures.

Data Cleansing

Codasol’s Prosol excels in finding inaccurate, poor, irrelevant, and inconsistent data from the data through the data cleansing process. It also involves removing duplicate data and correcting misspellings. This is done to feed the data into the predefined or formatted standard, which is prompt for the organization’s norms.

Data Integration

Merge and incorporate the different data sources with the standard format over multiple systems to create a unified master data record. Ensures this single record is super accessible across enterprises.

Data Validation

This step tests the data set to see whether the data meets the expected quality and richness. Data validation passes through pre-data entry to post-data entry level to ensure the data are qualified, on-trend, and valid for all the processes.

Data Governance and Stewardship

Implementing a comprehensive data governance strategy to assign data stewards, data ownership, and data accountability to oversee whether the data are collected, accessed, processed, maintained, and distributed with regulatory compliance.

Continuous Monitoring and Improvement

Organizations use software and data quality monitoring tools for regular audits and examine the dataset to adhere to the standardized formats

With the upcoming benefits of data standardization, an organization can make better decisions and increase the ROI.

Benefits of data standardization

Data Accuracy

Data standardization eliminates errors and inconsistency by setting up unique formats, which in turn results in accurate data for the complex data sets driven from areas such as seismic geological surveys, drilling, clinical and lab reports, inventory management, product specifications, etc.

Operational efficiency

Standardization minimizes the time spent on reducing errors, eliminating duplicates, and the manual data cleaning process. This standardized data fosters seamless data integration across different systems and departments, which breaks down operational slowdowns and ensures quick decision-making.

Cost reduction

Standardized data formats can lower costs spent on data cleaning, data handling, procurement, asset management, inventory optimization, research and development, data reconciliation, and supply chain management.

Enhanced decision-making

The outcomes of predictive analysis for the standardized data allow decision makers to make effective decisions in areas like resource estimation, production forecasting, and risk assessment in oil and gas; drug discovery research; treatments research; and clinical trial designs in pharma; product development; process optimization and market demand forecasting in manufacturing.

Even though data standardization improves comprehensive data management across industries like oil and gas, pharmaceuticals, and manufacturing, several challenges restrict the standardization process from keeping its promises. Some of the critical challenges are

Legacy systems and infrastructure

Organizations continue to rely on legacy systems, which retain outdated data that is difficult to standardize and integrate. Maintaining old systems to satisfy data standardization requirements is costly, time-consuming, and technically complex.

Resistance to change

Data standardization will change the existing workflow, tools, software, and techniques. This drives the employees or departments to reject new changes. Lack of employee involvement and slow implementation of the standardization process will lag the organization’s effectiveness.

Complexity in global operations

Industries like oil and gas, pharmaceuticals, and manufacturing need global data transformation for their growth. Organizations dealing with these industries will generate different languages, formats, and regulatory compliance. Standardizing these data and implementing complicated worldwide processes will need a significant amount of time and money.

Dynamic Nature of Data

Maintaining the old legacy systems with current data trends and patterns is highly challenging in data standardization. Organizations need to update their data from time to time in the ever-evolving data world to ensure their standardization process effectively.

Closing thoughts

Industries like oil and gas, pharmaceuticals, and manufacturing expand their potential data management with the help of data standardization. Its numerous benefits include improved data quality, operational efficiency, regulatory compliance, and better decision-making.

Our tool Prosol guarantees your industries to retain up to 20% ROI.