Efficient inventory management remains a critical success factor for industries such as Oil & Gas, Utilities, Construction, Healthcare, and Manufacturing, especially in complex environments across India, the GCC, and the Far East. Efficient systems can prevent overstocking, reduce downtime, and save millions. Among the most debated approaches are asset tagging vs UNSPSC code implementation. Both are powerful but serve very different purposes.

So, which of these two systems delivers real value?

In this blog, we dive deep into the strengths, weaknesses, and strategic applications of both methods—providing insights to help your business drive accuracy, compliance, and operational efficiency.

Understanding the Basics

What is Asset Tagging?

Asset tagging involves assigning unique identifiers (usually in the form of barcodes, QR codes, or RFID tags) to physical assets. These tags allow for real-time tracking, maintenance scheduling, and lifecycle management.

Common Applications:

- Fixed asset management

- Preventive maintenance

- Real-time asset tracking

- Depreciation management

What is UNSPSC Code Implementation?

UNSPSC (United Nations Standard Products and Services Code) is a globally recognized taxonomy for classifying products and services. Each item in your inventory is assigned a hierarchical code that standardizes procurement and reporting.

Common Applications:

- Material classification

- Spend analysis

- Strategic sourcing

- Procurement analytics

Asset Tagging vs UNSPSC Code Implementation: A Head-to-Head Comparison

| Criteria | Asset Tagging | UNSPSC Code Implementation |

|---|---|---|

| Purpose | Tracks physical assets | Classifies items/services for procurement |

| Visibility | Operational-level (asset location, usage) | Strategic-level (spend, supplier analytics) |

| Real-time Tracking | Yes | No |

| Standardization | Limited to internal standards | Global standard |

| Procurement Alignment | Not primary function | Core function |

| Lifecycle Management | Yes | No |

| Data Input Required | Serial numbers, asset type, location | Product/service description, manufacturer, usage type |

| Ideal Use Case | Equipment, tools, movable assets | Spare parts, consumables, MRO items |

| ROI Timeline | Quick for operational efficiency | Medium to long-term for sourcing savings |

Where Each Method Excels: Asset Tagging vs UNSPSC Code

Asset Tagging is Ideal When:

- Your team manages movable assets across remote or complex environments (e.g., offshore rigs, hospitals, logistics hubs).

- You need visibility into asset lifecycle, repair schedules, and audits.

- Theft prevention or loss detection is a concern.

- Your operations require real-time location tracking via RFID or GPS.

UNSPSC Code Implementation is Ideal When:

- You want to standardize procurement across departments and global vendors.

- Your goal is to enable data-driven sourcing decisions.

- Spend categorization, cost center alignment, and supplier performance are priorities.

- You’re aiming for digital transformation in procurement using ERPs like SAP, Oracle, or Maximo.

Which One Improves Inventory Management? Asset Tagging vs UNSPSC Code

The Answer: It’s Not Either/Or—It’s Both

For a truly optimized inventory system, a hybrid approach delivers the best results.

- Asset Tagging improves real-time operational control, asset traceability, and maintenance efficiency.

- UNSPSC Coding brings procurement consistency, cost visibility, and compliance with international procurement standards.

Together, they create a complete master data management strategy eliminating duplicates, reducing stockouts, and increasing return on assets.

Case in Point: Oil & Gas and EPC Industries

In Oil & Gas or EPC environments, where a single site can involve millions of material entries, a lack of standardization leads to bloated inventories and costly shutdowns.

Common Challenges:

- Duplicates in material master records

- No visibility of asset locations or conditions

- Inconsistent naming conventions across locations

Implementing asset tagging ensures that mobile and critical assets are accounted for, while UNSPSC codes ensure that all parts whether ordered locally or globally are classified consistently for purchasing and reporting.

Discover how asset tagging + classification strategy can save costs, reduce downtime, and boost efficiency across sites.

Key Benefits of Combining Both Systems

- Better Budget Control

Classify all spend with UNSPSC, track high-value equipment with tags. - Zero Duplicate Inventory

Avoid duplicate materials with standardized coding. - Faster Audits & Compliance

Regulatory or financial audits become easier with traceable assets and coded material masters. - Streamlined Procurement

Use consistent product codes for global tenders or vendor onboarding. - Preventive Maintenance Scheduling

Tagged assets can auto-trigger maintenance alerts or inventory reorder points.

Industries That Gain the Most

This dual strategy is especially beneficial for:

- Oil & Gas: Manage offshore rigs, refineries, and spares seamlessly.

- Real Estate & Construction: Track machinery, tools, and consumables across projects.

- Healthcare & Lifesciences: Tag equipment for compliance and classify pharmaceuticals.

- Marine & Ports: Manage equipment lifespan and spare parts reordering.

- Utilities & Energy: Track infrastructure assets and optimize maintenance budgets.

- Government & Defense: Enable accountability for high-value public assets.

- Banking: Ensure visibility of IT assets and standardize IT procurement.

Best Practices for Implementing a Dual Strategy:

- Start with a Material Master Clean-up

Use AI-based tools to eliminate duplicates and harmonize naming conventions. - Tag High-Value Assets First

Prioritize mobile or mission-critical items for RFID/barcode tagging. - Apply UNSPSC to Consumables & MRO

Use it for commodities, services, and frequently purchased parts. - Integrate with ERP

Ensure seamless integration with SAP, Oracle, Maximo, or other legacy systems. - Train Cross-Functional Teams

Procurement, operations, and finance should align on coding and tagging protocols.

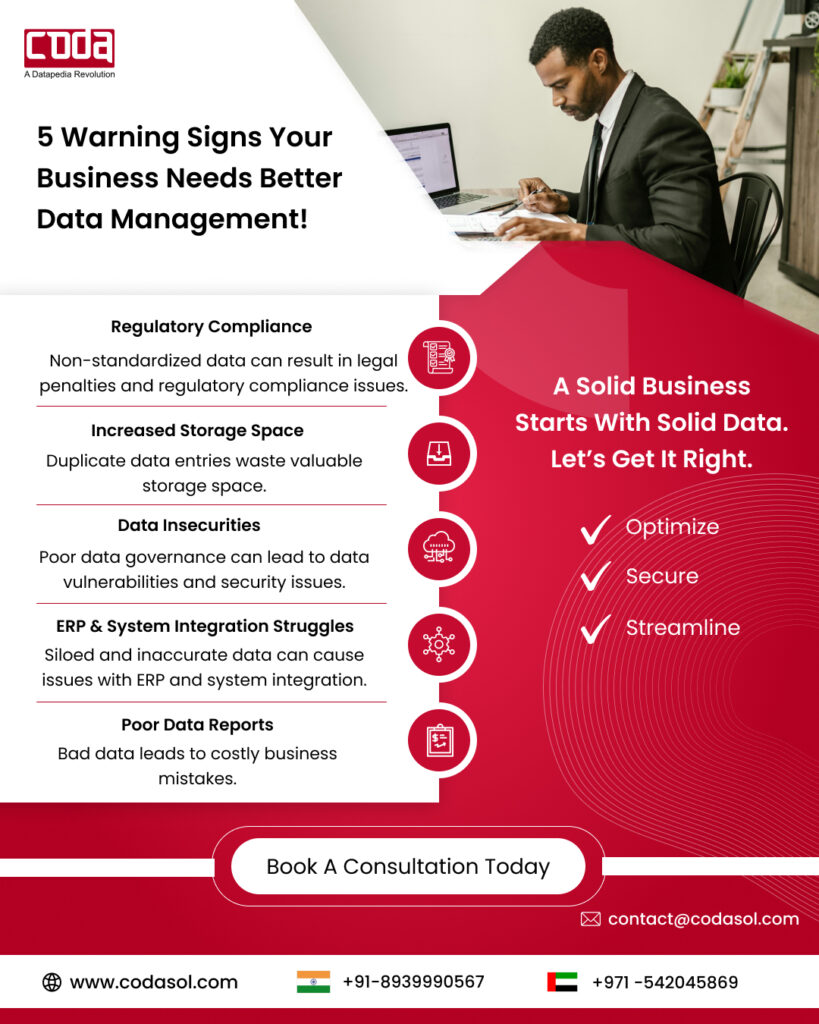

How CODASOL Supports Both Approaches

Asset Tagging: iStock

iStock is a next-gen asset tracking app developed by CODASOL.

It lets organizations effortlessly:

- Tag assets digitally (via QR, barcode, RFID)

- Track equipment across facilities and geographies

- Manage asset audits and maintenance schedules

- Integrate with ERP systems for real-time visibility

With mobile and web interfaces, iStock is designed for field operability and enterprise-grade data accuracy.

UNSPSC Code Implementation: Prosol

PROSOL is CODASOL’s flagship AI-powered platform for Master Data Management (MDM) that excels in:

- UNSPSC-based cataloging

- Automated deduplication and cleansing

- Enrichment with technical attributes

- Seamless integration with SAP, Oracle, Maximo, etc.,

Whether you’re managing 10,000 SKUs or 1 million, PROSOL provides the foundation for consistent, governed, and global-ready material master data.

We offer:

- Material Master Cleansing & Deduplication

- Asset & BOM Data Standardization

- UNSPSC-Based Material Classification

- Asset Tagging with Barcoding & RFID

- ERP Integration with SAP, Oracle, Maximo

- Inventory Digitization & Real-time Visibility

FAQ: Asset Tagging vs UNSPSC Code Implementation

Q1: Can I implement asset tagging without UNSPSC codes?

Yes, but your procurement process may still suffer from data silos and inconsistencies without standardized classification.

Q2: What is the ROI for implementing both?

Organizations often realize 3x to 5x ROI within 6–12 months through reduced duplication, better procurement, and faster audits.

Q3: Are these methods suitable for small organizations?

Absolutely. The key is to start small (critical assets and high-spend categories) and scale with automation.

Q4: What are some tools used for tagging and UNSPSC coding?

Tools like PROSOL from CODASOL, SAP MDM, IBM Maximo, and Oracle EDM can handle both tagging and UNSPSC mapping with ERP integration.

Q5: How long does implementation take?

Depends on scope and scale, but most mid-sized enterprises can implement both within 3–6 months with expert guidance.

Final Thoughts

When it comes to asset tagging vs UNSPSC code implementation, don’t choose one over the other. Combining both iStock and PROSOL gives your organization full control from the shop floor to the boardroom.

Whether you’re managing offshore platforms in the GCC, hospitals in India, or manufacturing hubs in Southeast Asia data-driven inventory management is your best defence against inefficiencies and losses.

Get actionable insights on how to digitize your asset base, implement UNSPSC, and build a best-in-class inventory strategy.