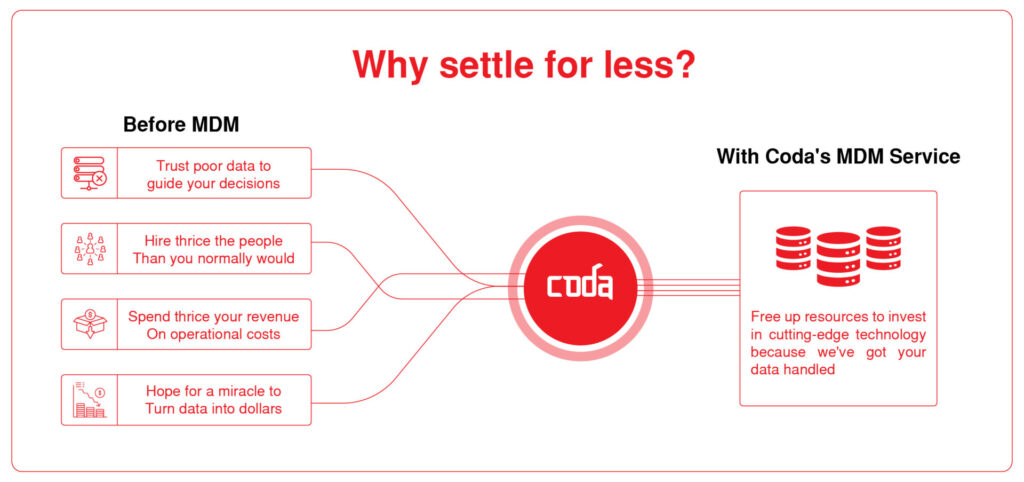

Master Data Management (MDM) in manufacturing is crucial for ensuring accurate, consistent data that drives efficiency and business growth. From inventory levels to production schedules, and even customer demands, manufacturers rely on a wealth of data daily. However, with data coming from numerous systems, departments, and locations, it can quickly become fragmented, inconsistent, or outdated, creating chaos and inefficiencies.

This is where Master Data Management (MDM) comes in. By ensuring that critical data remains accurate, consistent, and accessible across an entire organization, MDM becomes a powerful tool that can streamline processes, eliminate silos, and help to utilize the full potential of data.

With Master Data Management in manufacturing, manufacturers can centralize their data, reduce errors, and improve decision-making processes.

In this post, we’ll dive into how MDM plays an essential role in the manufacturing sector and explore the specific benefits it offers in terms of data accuracy, operational efficiency, and long-term business growth.

What is Master Data Management (MDM)?

At its core, Master Data Management (MDM) is a methodology and set of technologies that help organizations manage their most critical business data called “master data.” Master data is the consistent and uniform data that is used across various departments and systems in an organization.

In the manufacturing sector, this typically includes data on products, materials, suppliers, customers, assets, and even employees.

MDM ensures that this master data is accurate, consistent, and easily accessible by eliminating discrepancies, redundancies, and errors that could otherwise impede operations. Without MDM, manufacturers might end up with data silos, where different departments maintain their own version of critical data, leading to inefficiencies, errors, and missed business opportunities.

By consolidating and governing data in a single, centralized repository, MDM ensures that everyone in the organization is working with the same set of reliable, up-to-date information.

How MDM Ensures Data Accuracy in Manufacturing

Data accuracy is the backbone of any successful manufacturing operation. Inaccurate or inconsistent data can lead to production delays, supply chain disruptions, poor customer service, and ultimately, lost revenue. Let’s take a closer look at how MDM directly impacts data accuracy in the manufacturing industry.

1. Centralized Data Repository

One of the primary functions of MDM is to centralize data. Manufacturing companies often pull data from multiple systems— enterprise resource planning (ERP), supply chain management, inventory management, and more. MDM creates a centralized repository, consolidating this data into one unified source. This “single source of truth” ensures that all stakeholders, whether in the warehouse, on the factory floor, or in the finance department, are working with the same accurate data. This centralized approach drastically reduces the chances of discrepancies and data conflicts between systems and departments.

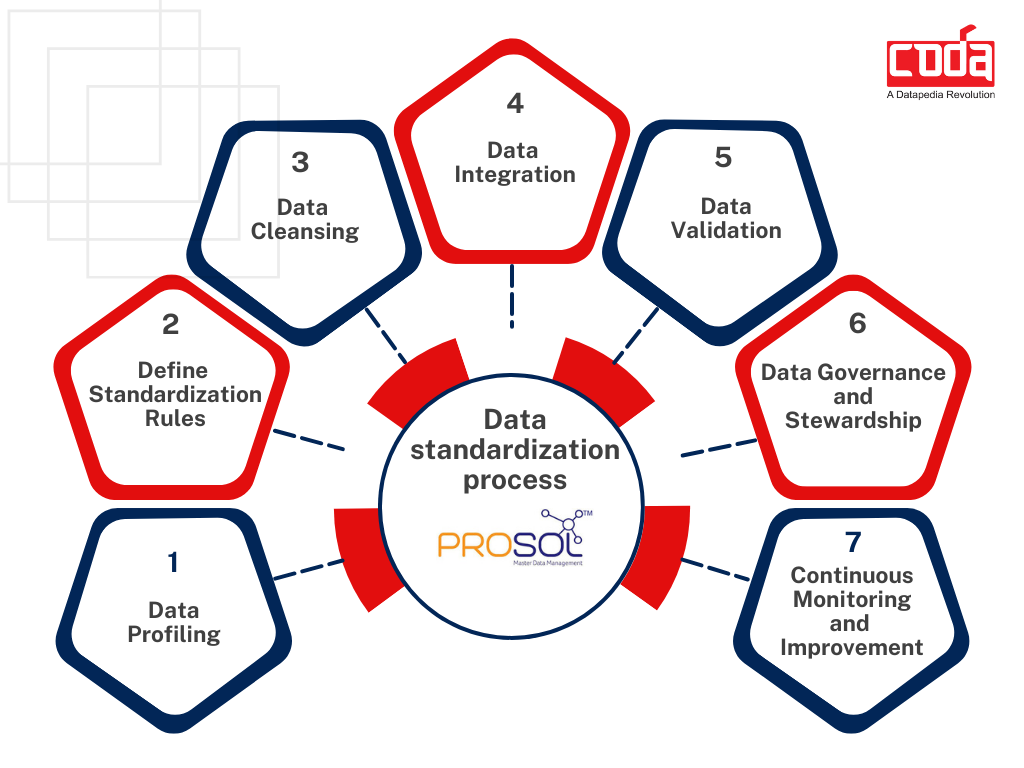

2. Data Cleansing and Validation

Master data is only valuable if it’s clean, validated, and consistent. Over time, data can become outdated, inaccurate, or duplicated. MDM systems employ data cleansing techniques to identify and remove duplicates, correct errors, and fill in missing values. By performing data validation checks, MDM ensures that the data being used for decision-making is always accurate. This is particularly important in manufacturing, where a simple data entry error could result in production delays or safety concerns.

3. Real-Time Data Accuracy

Manufacturers need to have access to accurate data in real-time, especially in today’s fast-paced, dynamic market. MDM allows for the continuous updating of master data across all systems. This real-time data accuracy ensures that stakeholders can make timely and informed decisions. Whether it’s responding to an urgent production order, adjusting inventory levels, or addressing customer inquiries, having accurate, up-to-date information available at the moment of need is invaluable.

Streamlining Processes with MDM in Manufacturing

Beyond improving data accuracy, MDM plays a key role in streamlining operations and optimizing manufacturing processes. Here are a few ways MDM enhances efficiency in the manufacturing industry:

1. Improved Supply Chain Visibility

In manufacturing, supply chain disruptions are a significant source of inefficiency and cost. MDM provides comprehensive visibility into every aspect of the supply chain by ensuring that data related to suppliers, inventory, production schedules, and customer orders is accurate and accessible in real-time. With this visibility, manufacturers can optimize their procurement strategies, minimize lead times, and reduce the likelihood of stockouts or overstocking. By leveraging MDM, manufacturers can better predict demand, improve inventory management, and create a more responsive supply chain.

2. Enhanced Production Scheduling

Production scheduling is a complex process that involves managing raw materials, machinery, labor, and time to ensure products are made efficiently. MDM helps streamline production scheduling by ensuring that all data such as material availability, machine uptime, and employee shifts— is accurate and accessible in real-time. With consistent data, manufacturers can avoid delays, prevent bottlenecks, and optimize the utilization of resources, resulting in a more efficient and cost-effective production process.

3. Simplified Compliance and Reporting

Manufacturing companies are often subject to strict industry regulations and standards. These regulations require accurate documentation and reporting to ensure compliance. MDM plays a crucial role in simplifying compliance and reporting by ensuring that all data related to quality standards, safety protocols, and regulatory requirements is consistent and up-to-date. With clean and validated master data, manufacturers can more easily generate accurate reports for regulators, auditors, and stakeholders, reducing the risk of penalties and compliance failures.

4. Faster Decision-Making

MDM ensures that decision-makers have access to reliable, timely data, which is key to fast and informed decision-making. Whether it’s adjusting production schedules, addressing supply chain disruptions, or responding to customer demands, MDM enables manufacturers to make decisions based on accurate, up-to-date information. In an industry where agility is crucial, this ability to make faster decisions helps manufacturers stay competitive and responsive to market changes.

Would you like to know how we helped to maintain accurate and consistent Master Data across an entire organization?

How Master Data Management in Manufacturing Drives Long-Term Business Growth

While MDM is essential for operational efficiency, its benefits extend far beyond day-to-day operations. In fact, MDM is a key enabler of long-term business growth in the manufacturing sector. Let’s explore how:

1. Cost Reduction

By improving data accuracy and operational efficiency, MDM helps manufacturers reduce costs in several ways. First, it minimizes inventory costs by optimizing stock levels and reducing overstocking or stockouts. Second, it lowers production costs by ensuring that resources (materials, labor, and machinery) are utilized efficiently. Lastly, it cuts down on the costs associated with errors and delays, which can be significant in manufacturing. By improving processes and eliminating inefficiencies, MDM helps manufacturers lower their overall operating costs.

2. Better Customer Satisfaction

Customer satisfaction is vital for long-term success. MDM helps manufacturers deliver better customer service by ensuring that orders are fulfilled accurately and on time. With MDM, manufacturers can track inventory levels, manage production schedules, and monitor shipping timelines in real-time, ensuring they meet customer expectations. Also, with accurate product data, manufacturers can offer more personalized products and services, leading to higher customer satisfaction and loyalty.

3. Scalability and Flexibility

As manufacturing businesses grow, they need to scale their operations and adapt to new challenges. MDM provides the flexibility and scalability needed to support growth. With a centralized system for managing critical data, manufacturers can easily integrate new systems, expand to new markets, and add new product lines without disrupting operations. MDM ensures that data remains consistent and accurate, no matter how large or complex the organization becomes.

4. Data-Driven Innovation

Innovation is a key driver of business growth. MDM enables manufacturers to harness clean, consistent data to identify opportunities for innovation. Whether it’s developing new products, improving existing ones, or finding efficiencies in operations, MDM empowers manufacturers to use data-driven insights to drive continuous improvement. With access to accurate master data, manufacturers can identify trends, customer preferences, and market demands, enabling them to stay ahead of the competition and continually evolve.

Conclusion:

The Critical Role of MDM in the Manufacturing Sector

Implementing Master Data Management in Manufacturing not only enhances data accuracy but also streamlines workflows, ensuring that every department has access to the same reliable information.

By ensuring that critical data is accurate, consistent, and accessible across the entire organization, MDM enables manufacturers to optimize operations, reduce costs, and improve decision-making. As a result, manufacturers can improve their supply chain visibility, streamline production scheduling, simplify compliance, and ultimately drive long-term business growth.

In today’s data-driven world, the importance of MDM cannot be overstated. It provides manufacturers with the clarity and control they need to stay competitive, respond quickly to market changes, and make informed decisions that propel their business forward.

Key Takeaways

- Centralized Data: MDM provides a single source of truth for all critical data, improving accuracy and consistency.

- Data Cleansing: MDM eliminates errors, duplicates, and inconsistencies to ensure reliable data.

- Improved Operations: MDM streamlines processes like supply chain management, production scheduling, and compliance reporting.

- Long-Term Growth: MDM drives growth by reducing costs, improving customer satisfaction, and enabling data-driven innovation.

Master Data Management is essential for any manufacturer looking to optimize their operations and achieve sustainable growth. By focusing on accurate, consistent data, manufacturers can unlock new opportunities for efficiency, profitability, and success in an increasingly competitive industry.

Is your manufacturing business ready to take control of its data?

Reach out to us today to discover how our Master Data Management solutions can help streamline your operations and drive long-term growth.