Data accuracy and consistency are crucial for the importance of Master Data Management in manufacturing, ensuring operational efficiency, cost reduction, and a competitive edge. Manufacturers handle complex supply chains, multiple product lines, and diverse customer demands, making effective master data management essential for seamless operations.

This is where Master Data Management (MDM) comes into play. MDM ensures that all critical business data like product specifications, supplier details, customer records, and inventory information is standardized, accurate, and up to date.

In this blog, we’ll explore:

- What Master Data Management (MDM) is

- Why MDM is crucial for manufacturing operations

- The challenges manufacturers face without MDM

- How to overcome these challenges

- Competitor comparison

- FAQs about MDM in Manufacturing

Let’s dive in.

What is Master Data Management (MDM)?

Master Data Management (MDM) is the process of collecting, organizing, and governing critical business data in a centralized system to ensure consistency, accuracy, and reliability.

In manufacturing, MDM helps standardize product data, BOM (Bill of Materials), supplier information, inventory records, and customer details across multiple systems, improving decision-making and operational efficiency.

🔗 Read More: What is Master Data Management and How Does It Work?

Why is Master Data Management Important for Manufacturing?

1. Ensures Data Consistency

- Reduces duplicate or conflicting records across different departments.

- Maintains a single source of truth for product, supplier, and customer data.

2. Improves Decision-Making

- Helps managers access real-time, reliable data for strategic planning.

- Reduces the risk of errors in forecasting and inventory management.

3. Reduces Operational Costs

- Minimizes errors in product specifications and BOM, reducing rework.

- Optimizes procurement costs by improving supplier negotiations.

4. Enhances Supply Chain Efficiency

- Centralizes supplier and inventory data for better procurement strategies.

- Prevents stockouts and overstocking by providing accurate demand forecasts.

5. Strengthens Compliance & Risk Management

- Ensures regulatory compliance by maintaining accurate product and material records.

- Reduces financial losses caused by data inconsistencies and errors.

6. Increases Revenue & Business Growth

- Enables data-driven marketing and sales strategies for better customer targeting.

- Improves customer satisfaction with accurate order fulfillment and delivery tracking.

🔗 Read More: Must-Have Features in a Master Data Management (MDM) Product

Cloud-Based vs. On-Premise MDM Solutions

| Feature | Cloud-Based MDM | On-Premise MDM |

|---|---|---|

| Deployment | Hosted on cloud servers, accessible via the internet | Installed on a company’s own servers and infrastructure |

| Scalability | Highly scalable, can easily adjust to business needs | Limited by on-premise hardware capacity |

| Cost | Lower upfront costs, subscription-based pricing | Higher initial investment, ongoing maintenance costs |

| Security | Security managed by cloud provider, with built-in compliance | Full control over data security but requires internal security measures |

| Integration | Easily integrates with various cloud-based applications | Requires more effort for integration with existing enterprise systems |

| Maintenance & Updates | Automatic updates and maintenance handled by the cloud provider | Manual updates and maintenance required by in-house IT team |

| Performance | Dependent on internet speed and cloud provider reliability | Higher performance consistency with local infrastructure |

| Compliance | Compliance handled by cloud vendor but may raise concerns about data residency | Full compliance control based on internal policies |

| Business Continuity | Built-in disaster recovery and backup options | Backup and recovery must be managed in-house |

| Best for | Businesses looking for flexibility, scalability, and lower upfront costs | Companies needing complete control over data and infrastructure |

Challenges Faced Without MDM in Manufacturing

1. Data Silos

- Departments use isolated databases, making data difficult to share and access.

- Leads to inconsistent inventory records and procurement errors.

Solution:

- Integrate ERP, supply chain, and production systems into a single MDM platform.

- Implement data governance policies to ensure data accuracy across all teams.

2. Poor Data Quality

- Incomplete, outdated, or inconsistent data results in faulty reporting and forecasts.

Solution:

- Use automated data validation rules to detect and fix errors.

- Apply AI-driven analytics to improve sensor readings and inventory accuracy.

3. Scalability Issues

- Expanding operations generate massive data volumes, making management difficult.

Solution:

- Implement cloud-based MDM for scalable storage and processing.

- Use automated workflows to handle data entry and validation.

4. Security Risks

- Manufacturing data is vulnerable to cyberattacks, insider threats, and IP theft.

Solution:

- Implement multi-factor authentication (MFA) and role-based access control.

- Use real-time threat detection to safeguard sensitive data.

5. High Implementation Costs

- Implementing MDM can be costly and time-consuming for manufacturers.

Solution:

- Start with essential MDM features and scale gradually.

- Choose cloud-based MDM solutions to reduce infrastructure costs.

Competitor Comparison (MDM Tool):

| Feature | CODASOL | Prospecta | Pilog |

|---|---|---|---|

| Industry Focus | Manufacturing, Oil & Gas, Chemicals, Utilities | General MDM | General MDM |

| Data Cleansing & Standardization | AI-driven, automated | Semi-automated | Semi-automated |

| Duplicate Data Detection | Advanced ML-based deduplication | Limited | Limited |

| AI & ML Capabilities | AI-powered insights & recommendations | Basic automation | Basic automation |

| ERP Integration | SAP, Oracle, Maximo, Microsoft Dynamics | SAP, Salesforce | SAP, Salesforce |

| Automated Workflows | End-to-end automation | Partial automation | No automation |

| Cloud & On-Premise Deployment | Both | Both | Both |

| Scalability for Large Enterprises | High scalability with cloud AI | Moderate | Moderate |

| Real-Time Data Synchronization | Yes, instant updates across systems | No | No |

| Security & Compliance | Advanced security (ISO, GDPR, industry-specific compliance) | Basic compliance | Basic compliance |

| Supply Chain Optimization | AI-powered demand forecasting & supplier management | No | No |

| Custom Reporting & Dashboards | Fully customizable, AI-powered insights | Limited customization | Limited customization |

| Implementation Speed | Fastest, minimal downtime | Slow, high downtime | Slow, high downtime |

| Pricing | Cost-effective for enterprises | Expensive | Expensive |

| Best For | Manufacturers needing AI-driven MDM for accurate inventory, supplier, and production data | Businesses with general MDM needs | Businesses with general MDM needs |

Key Takeaways:

- CODASOL outperforms both Prospecta and Pilog with its AI-driven data management, automation, and advanced ERP integration.

- If you’re in manufacturing, oil & gas, or utilities, CODASOL is the only provider tailored to your industry.

- Prospecta and Pilog are more general MDM solutions with limited automation and AI capabilities.

Why Choose CODASOL?

- Specialized in manufacturing MDM solutions.

- AI-driven data cleansing for accuracy.

- Seamless ERP integration with SAP, Oracle & Maximo.

🔗 Check Out CODASOL’s MDM Solutions: Learn More

Frequently Asked Questions (FAQs)

1. What is Master Data Management (MDM) in manufacturing?

MDM in manufacturing ensures that all critical business data, such as materials, inventory, suppliers, and product specifications, is accurate, consistent, and standardized across different systems like ERP, PLM, and SCM. This eliminates data silos, reduces errors, and improves operational efficiency.

2. Why is MDM critical for manufacturers?

MDM is essential because it reduces duplicate materials and optimizes inventory. It prevents production delays caused by inaccurate supplier or part information. It improves procurement efficiency, leading to cost savings, and ensures regulatory compliance by maintaining accurate records.

3. What challenges do manufacturers face without MDM?

Without MDM, manufacturers often experience inaccurate inventory data, leading to overstocking or shortages. Duplicate materials increase procurement and storage costs. Supplier inconsistencies cause production delays, and compliance risks lead to regulatory fines. Disconnected systems also reduce overall efficiency.

4. How does MDM improve supply chain management?

MDM ensures clean, standardized supplier and material data, enabling faster supplier onboarding and approval, accurate lead time estimation, optimized procurement strategies, and better demand forecasting. This results in a resilient and cost-effective supply chain.

5. How does AI enhance Master Data Management?

AI-powered MDM solutions provide automated data deduplication to remove duplicate SKUs, intelligent data classification for streamlined cataloging, predictive analytics for demand planning and supplier risk assessment, and real-time data synchronization across multiple systems.

6. What is the ROI of implementing MDM in manufacturing?

MDM delivers a high return on investment by reducing material duplication, preventing unplanned downtime due to incorrect parts data, lowering inventory carrying costs with optimized stock levels, and improving decision-making with AI-driven insights. A well-implemented MDM system can pay for itself within six to twelve months.

7. How does MDM integrate with ERP systems like SAP or Oracle?

A robust MDM solution seamlessly integrates with SAP, Oracle, Maximo, and other ERP systems by providing a single source of truth for materials, suppliers, and BOMs. It ensures real-time data updates across all connected systems and automates workflows to reduce manual data entry and errors.

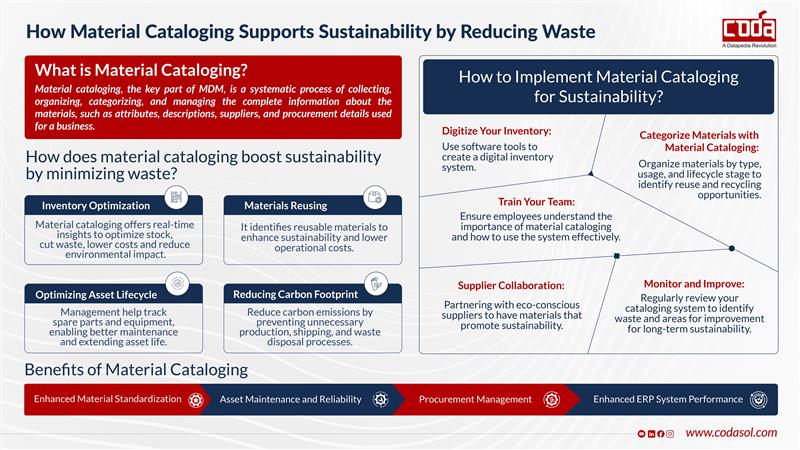

8. Can MDM help with sustainability in manufacturing?

Yes, MDM supports sustainability efforts by reducing material waste through better inventory management, enhancing circular economy initiatives by identifying reusable or excess materials, and tracking environmental compliance data for sustainable sourcing.

9. What should manufacturers look for in an MDM solution?

Key features to consider include AI-driven data cleansing and deduplication, seamless integration with ERP and SCM systems, scalability for global manufacturing operations, advanced reporting and analytics, and automated workflows to reduce manual work.

10. Why choose CODASOL over other MDM providers?

CODASOL specializes in AI-driven MDM for manufacturing, offering faster implementation with minimal downtime, real-time data synchronization across ERP and SCM, industry-specific features tailored for manufacturers, and automated material deduplication that saves millions in procurement costs.

Conclusion

Implementing Master Data Management (MDM) in manufacturing is no longer an option.

- Without MDM, manufacturers face data silos, inefficiencies, and increased costs.

- With MDM, businesses benefit from data consistency, cost savings, supply chain optimization, and compliance assurance.

By choosing CODASOL, manufacturers gain an AI-powered, scalable, and industry-specific MDM solution that outperforms competitors.

Explore CODASOL’s MDM Solutions Today