In industries such as Oil & Gas, Utilities, Manufacturing, Real Estate & Construction, Marine & Ports, Healthcare & Life Sciences, Banking, Minerals & Metals, Government Entities, Defense, EPC, and Aviation, efficient procurement is crucial for cost savings and operational success. However, organizations often struggle with material identification, duplicate inventory, and slow procurement cycles. Often struggles between Material Code Creation vs. Data Cataloguing.

But which one delivers better procurement efficiency?

Understanding Material Code Creation & Data Cataloguing

What is Material Code Creation?

Material Code Creation involves assigning a unique alphanumeric identifier to each item in the inventory. These codes standardize procurement, minimize errors, and improve traceability. However, maintaining uniform coding across multiple locations and vendors can be complex.

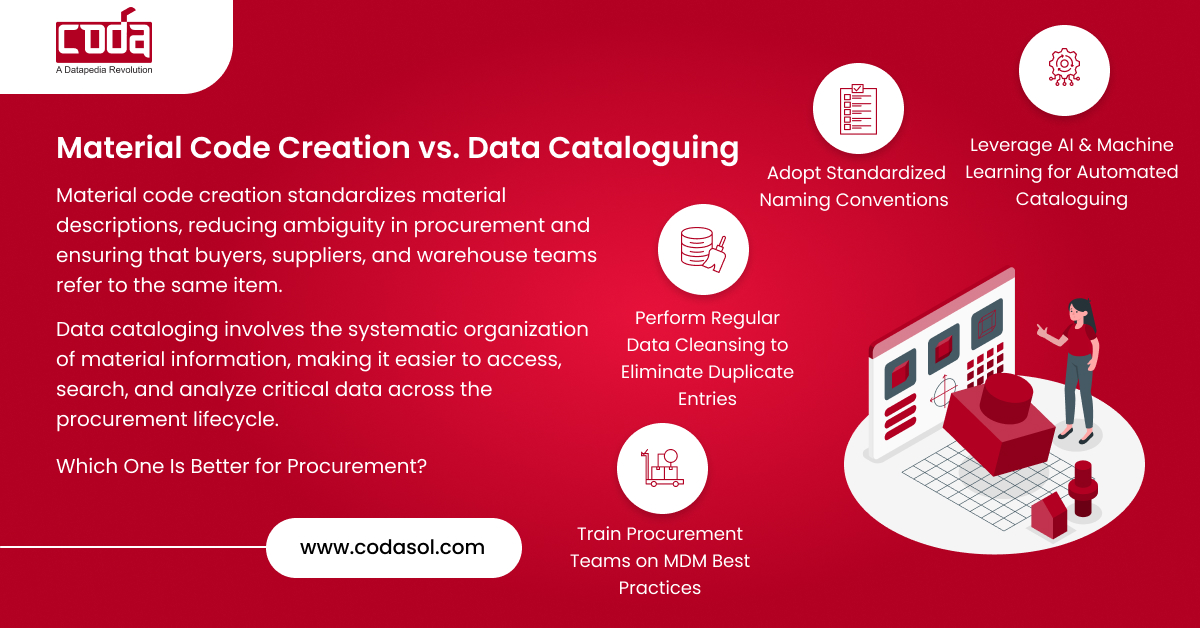

Material code creation is a fundamental process in procurement that assigns a unique identifier to each item in inventory. This coding system standardizes material descriptions, reducing ambiguity in procurement and ensuring that buyers, suppliers, and warehouse teams refer to the same item.

A well-defined material coding structure eliminates duplication, streamlines purchase orders, and improves spend analysis. However, while material codes help in identification, they alone do not provide a comprehensive view of material attributes, specifications, or availability, which is crucial for optimizing procurement decisions.

Explore how automated cataloguing can enhance procurement efficiency

What is Data Cataloguing?

Data Cataloguing classifies materials based on attributes such as specifications, manufacturer details, and usage. It improves searchability, enhances decision-making, and allows seamless integration with procurement systems. Unlike rigid material codes, cataloguing uses natural language descriptions for better usability.

Data cataloguing involves the systematic organization of material information, making it easier to access, search, and analyze critical data across the procurement lifecycle. This approach directly drives procurement efficiency by improving decision-making, enabling better inventory management, and optimizing supplier selection.

Unlike basic material codes, cataloguing solutions like PROSOL enrich material data with industry-standard classifications (ISO 8000, UNSPSC, ECLASS), detailed descriptions, and real-time updates. This ensures procurement teams can quickly find, compare, and validate materials before purchase, reducing duplicate orders and enhancing supplier negotiations. By integrating with ERP systems, data cataloguing improves visibility across departments, leading to better-informed purchasing decisions and cost savings.

Also Read:

Comparison: Material Code Creation vs. Data Cataloguing

| Aspect | Material Code Creation | Data Cataloguing |

|---|---|---|

| Identification | Unique, standardized codes | Categorized, searchable data |

| Complexity | Requires strict governance | Intuitive and user-friendly |

| Scalability | Difficult for large inventories | Easily scalable across locations |

| Data Accuracy | Risk of duplicate entries | Structured and consistent |

| Implementation | Time-consuming setup | Faster adoption with automation |

| Procurement Speed | Slower due to manual processes | Faster due to enhanced searchability |

Which One is Better for Procurement?

- Material Code Creation is ideal for industries where compliance, precision, and traceability are critical (e.g., Aerospace, Defense, Healthcare).

- Data Cataloguing is better for businesses that require scalable, analytics-driven procurement with quick searchability (e.g., EPC, Manufacturing, Marine & Ports).

Also Read:

Best Approach: A Hybrid Model

Rather than choosing one over the other, businesses should combine both:

- Use Material Codes for critical inventory that requires precise tracking.

- Implement Data Cataloguing for seamless procurement and supply chain analytics.

How to Improve Procurement Efficiency in India

- Leverage AI & Machine Learning for Automated Cataloguing

- Adopt Standardized Naming Conventions (ISO 8000, UNSPSC, ECCMA)

- Integrate Data Catalogues with ERP & Procurement Platforms

- Perform Regular Data Cleansing to Eliminate Duplicate Entries

- Train Procurement Teams on Master Data Management Best Practices

Conclusion

While Material Code Creation ensures accuracy and compliance, Data Cataloguing accelerates procurement cycles by improving searchability and reducing errors. The most efficient procurement strategy is to combine both methods, allowing businesses to optimize sourcing, eliminate inefficiencies, and enhance overall supply chain performance.

Frequently Asked Questions (FAQ)

1. Can Material Code Creation and Data Cataloguing be used together?

Yes, businesses benefit from using both methods. Codes ensure standardization, while cataloguing improves searchability and analytics.

2. What is the biggest challenge with Material Code Creation?

It requires strict governance and maintenance to avoid duplication and inconsistencies.

3. How does Data Cataloguing improve procurement?

It enables faster searches, better vendor comparisons, and enhanced reporting, leading to informed purchasing decisions.

4. Which industries in India benefit the most from each method?

- Material Code Creation: Aerospace, Defense, Healthcare, Oil & Gas.

- Data Cataloguing: EPC, Manufacturing, Utilities, Real Estate, Marine & Ports.

5. How can companies in India implement an efficient procurement strategy?

By adopting AI-driven cataloguing, ERP integration, and standardized data governance frameworks to streamline procurement.

Take the Next Step

Eliminate Duplicate Data & Reduce Procurement Costs

Our experts can help you cleanse and standardize your material master