The Oil & Gas industry, especially in the GCC region, has always faced challenges related to uptime and operational efficiency. The high cost of downtime, coupled with the push for more sustainable operations, has led to a rising demand for more advanced maintenance strategies. RCM in Oil & Gas is a methodical process that enhances maintenance strategies by prioritizing critical assets and assessing their potential failure modes.

It focuses on improving the reliability and performance of assets through a thorough understanding of their operating conditions, performance data, and failure modes. In a region where oil production drives economic growth, the push towards zero downtime operations is essential. This blog explores why RCM is becoming the cornerstone of the GCC Oil & Gas sector’s operations and its impact on ensuring seamless production, higher profits, and sustainability.

What is Reliability-Centered Maintenance (RCM)?

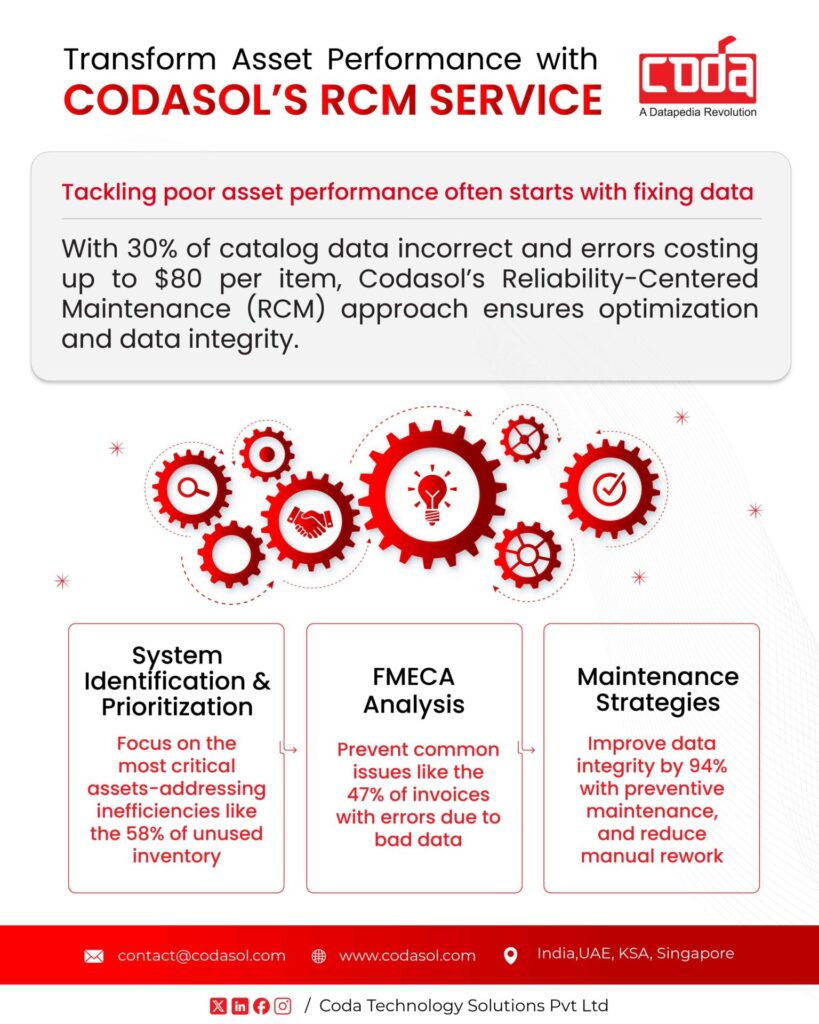

Reliability-Centered Maintenance (RCM) is a structured approach used to identify the most effective and efficient ways to maintain equipment, ensuring that it continues to operate at peak performance. Instead of relying on traditional reactive or preventive maintenance models, RCM employs a deeper understanding of system behavior, focusing on how to manage potential failures before they disrupt operations.

In RCM, organizations identify:

- Critical assets and equipment

- Potential failure modes

- Consequences of failures on production and safety

- Maintenance strategies (predictive, preventive, or corrective) to mitigate risks

RCM in Oil & Gas focuses on identifying the most effective and cost-efficient maintenance strategies for each piece of equipment, whether through predictive, preventive, or corrective maintenance. The goal is to eliminate unnecessary downtime, enhance safety, and optimize resource use, all while reducing operational costs.

Mohamed Altaf, Practice Head – Reliability Service at CODASOL has some expert insights on leveraging Predictive Maintenance to boost asset reliability and optimize operations

Why GCC’s Oil & Gas Sector is Adopting RCM

The GCC Oil & Gas sector is increasingly turning to RCM as a solution to several industry challenges. The region’s oil production facilities are vast and complex, requiring highly efficient and reliable maintenance systems to ensure smooth operations. Below are some key reasons why RCM is becoming essential in the GCC’s Oil & Gas sector:

1. Minimizing Unplanned Downtime

Unplanned downtime in oil fields and refineries is costly. When equipment fails unexpectedly, the impact is not just in terms of lost production but also additional repair and replacement costs. RCM helps identify failure-prone components before they fail, allowing companies to schedule maintenance during non-productive hours, minimizing downtime and its associated costs.

2. Improved Safety Standards

The Oil & Gas sector is one of the most hazardous industries globally. Failure of critical equipment can lead to catastrophic accidents, environmental damage, and loss of life. RCM focuses on identifying failure modes that could lead to safety risks and provides maintenance solutions to prevent these from happening. The proactive nature of RCM allows companies to enhance workplace safety and comply with regulatory standards.

Is your Oil & Gas business ready for a seamless future?

Explore how Reliability-Centered Maintenance can transform your operations. Contact us for a personalized consultation.

3. Cost Reduction and Operational Efficiency

With rising operational costs, oil companies need strategies to optimize their spending. RCM helps in eliminating unnecessary preventive maintenance tasks and focusing only on those that matter. By using predictive maintenance techniques, RCM ensures that resources are utilized effectively, improving operational efficiency while reducing the overall cost of maintenance.

4. Sustainability and Resource Optimization

Sustainability has become a critical factor in the Oil & Gas sector, especially with global climate change initiatives. RCM not only ensures the longevity of assets but also helps in optimizing resource use. Well-maintained equipment runs more efficiently, which leads to lower energy consumption and reduced emissions.

5. Adapting to Industry 4.0 Technologies

As part of the digital transformation in the Oil & Gas sector, the GCC is rapidly adopting Industry 4.0 technologies. RCM is aligned with these advancements, as it integrates seamlessly with IoT sensors, AI-driven analytics, and predictive maintenance tools. This combination allows for data-driven insights into equipment health, helping maintenance teams perform timely interventions.

How RCM Benefits Other Key Industries in the GCC and Far East

While the focus here is on the Oil & Gas sector, other industries in the GCC and Far East are also benefiting from RCM principles. Industries such as manufacturing, utilities, and construction can leverage RCM to enhance their operations and increase profitability.

1. Utilities

For utility companies, equipment reliability is crucial for maintaining uninterrupted services. RCM can help in predicting failures in power plants, transmission lines, and other critical infrastructure, ensuring that any potential disruptions are prevented, thus reducing operational risks.

2. Manufacturing

Manufacturers rely on production lines that must be operational around the clock. Using RCM, manufacturers can ensure that critical equipment is maintained properly, increasing productivity while minimizing unplanned downtime and enhancing product quality.

3. Marine & Ports

Shipping companies and ports face significant downtime costs due to unplanned maintenance of vessels and port equipment. RCM allows for better asset management and scheduling, which translates to a more reliable shipping and logistics operation.

4. Healthcare & Lifesciences

In the healthcare industry, equipment failures can directly impact patient care. RCM ensures that critical equipment, such as diagnostic machines, is maintained properly, reducing the risk of malfunctions that could affect patient outcomes.

RCM in Action: Key Benefits and Results

| Benefit | Impact on Operations | Example in GCC Oil & Gas |

|---|---|---|

| Minimized Downtime | Reduced unplanned outages, ensuring continuous operations | Predicting pump failures before they happen, preventing 24-hour stoppage |

| Improved Safety | Fewer accidents, better compliance with safety standards | Identifying potential hazardous equipment failures in drilling rigs |

| Cost Efficiency | Reduced maintenance and operational costs | Lowering the cost of emergency repairs with predictive maintenance models |

| Increased Asset Life | Extended equipment life and reduced capital expenditures | Prolonging the life of compressors and turbines used in offshore platforms |

Future of RCM in Oil & Gas Sector

The GCC’s Oil & Gas sector is not just adopting RCM for its short-term benefits but is positioning itself for long-term sustainability. As Industry 4.0 continues to evolve, the integration of IoT, big data, and predictive analytics will drive the next wave of innovation in RCM. By embracing these technologies, GCC oil companies can further optimize their maintenance strategies, reduce downtime, and improve overall productivity.

FAQ

Q1: How does RCM help reduce downtime in Oil & Gas operations?

RCM uses predictive analytics and deep system insights to identify potential failure points. This allows companies to schedule maintenance before equipment fails, minimizing downtime and costly repairs.

Q2: Can RCM be applied to other industries outside Oil & Gas?

Yes, RCM is effective across various sectors, including manufacturing, utilities, healthcare, marine, and more. Any industry that relies on critical equipment can benefit from RCM.

Q3: What are the costs associated with implementing RCM?

The initial cost of implementing RCM can vary based on the scale of operations and technology integration. However, the long-term savings in reduced downtime, maintenance costs, and improved asset efficiency often outweigh these costs.

Q4: How does RCM integrate with Industry 4.0 technologies?

RCM works seamlessly with IoT sensors, AI-driven analytics, and predictive maintenance tools, allowing real-time monitoring and data-driven decisions that enhance operational efficiency.

Q5: What is the future of RCM in the GCC Oil & Gas sector?

With the ongoing adoption of digital technologies, the future of RCM in the GCC Oil & Gas sector looks promising. The integration of advanced AI, big data, and IoT will further enhance RCM capabilities, driving efficiency and sustainability.

By adopting RCM, the GCC Oil & Gas sector is setting a new benchmark in maintenance strategy, pushing towards zero downtime operations and fostering greater sustainability. As other industries across the region also begin to leverage RCM, it will undoubtedly become a key component of business strategy for years to come.

Discover the power of predictive maintenance

Get in touch with our team to learn how RCM can reduce downtime and save costs in your industry.